The Dillon XL650 and the Dillon XL750 are among the very best progressive reloading presses and one of the most popular on the market today.

It’s optional motorized case feeder is an excellent accessory, and highly recommended for those who can afford it. But it does add a substantial cost to the price of the XL650/750.

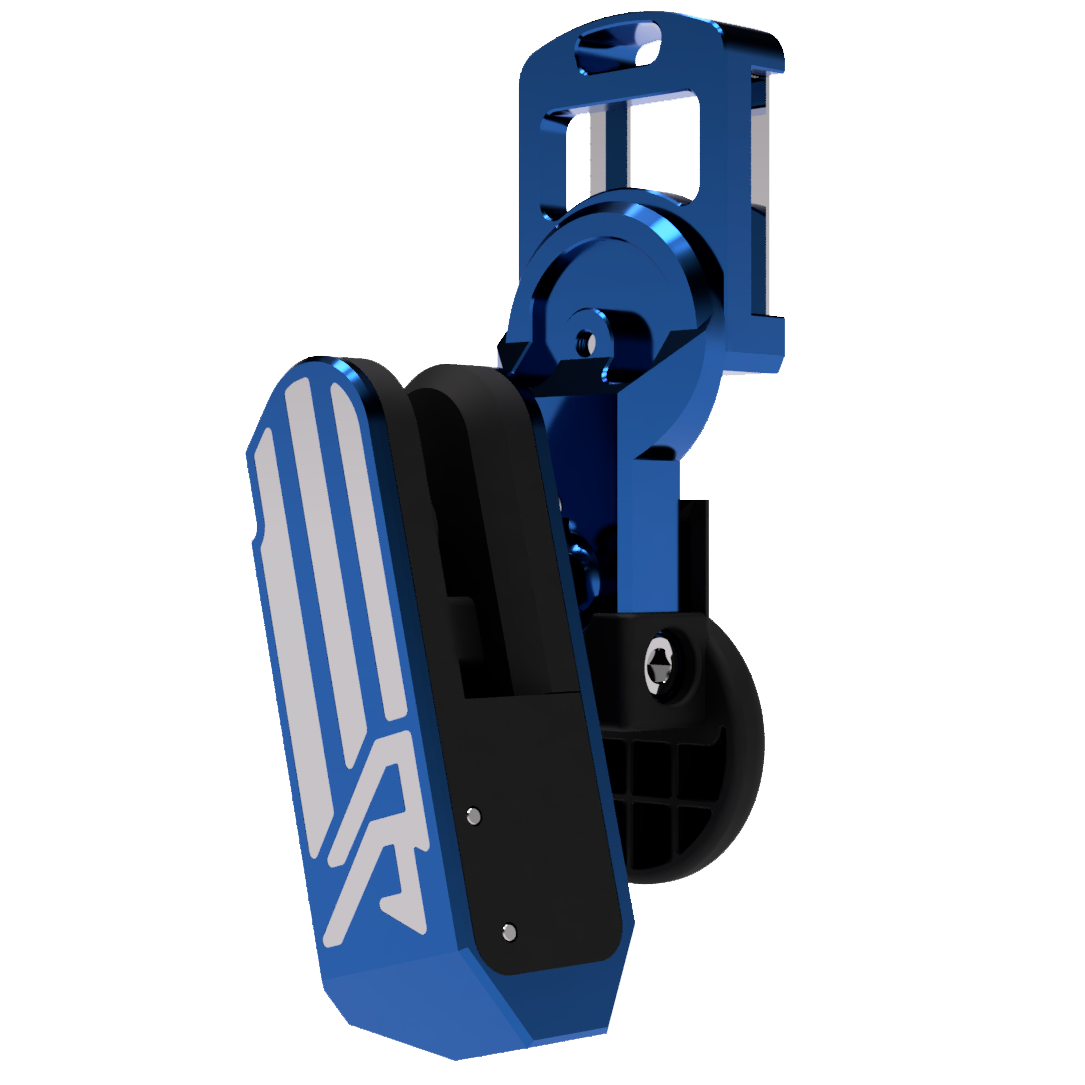

Many customers choose to start reloading on their XL650/750 without the optional case feeder, and for them the new DAA Mini Case feeder will be a great addition to their press!

In a few short minutes, perhaps while watching your favorite TV show, you can pre-hand-load the 6 tubes of the magazine assembly which will hold a combined 150 pcs of 9mm brass (about 130 of .40, or 120 of 38S).

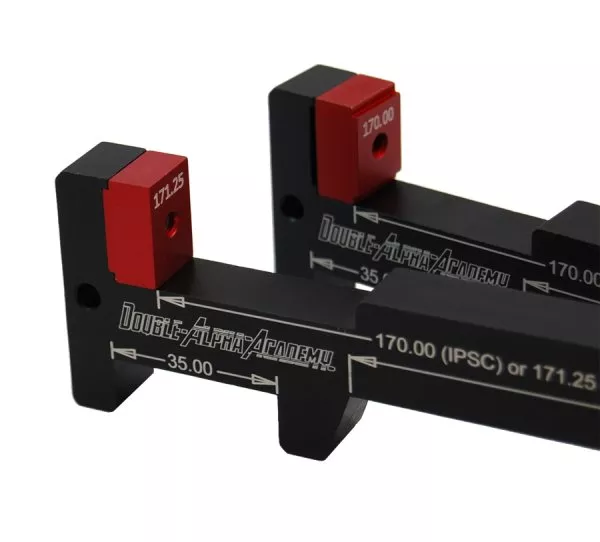

Using the included DAA Adaptor-Set parts, you simply seat the Magazine atop your XL650/750 using your Casefeed Adaptor, click the first tube into place – and you are ready to go. Each time a tube empties out, click the next one into position and continue reloading.

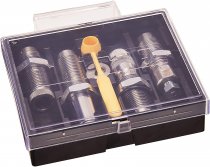

The DAA Mini Multi-Cal XL650 Case Feeder includes One 6-tube magazine assembly, and one Multi-Cal Adaptor-Set. Since the new design uses your original caliber specific Casefeed Adaptor, you can now use your DAA Mini Multi-Cal XL650/750 Case Feeder to feed brass in any caliber (excluding .44, .45).

It is ONE product, which can be used to handle: 9mm, 38S, 38SPL, 357, 0.40, 10mm, 223 and more.

Additional Magazine Assemblies can be purchased separately should you wish to prepare more than 150 pcs of brass before starting to reload.

Please note:

- The Multi-Cal Adaptor-Set is designed to fit snugly onto the Dillon Casefeed Adaptor tubes. If too tight, it may be difficult to remove to clear jams. If too loose, the assembly may wobble or cant a little. There is a slight variance between the various Dillon Casefeed Adaptor tubes, so some light fitting may be needed for a fit perfect to your needs. You can use a file, sandpaper or dremmel to slightly increase the inner dimension of the Support-Ring part.

- When filling the tubes, rotate the base of the assembly so that it is positioned between tubes- that way none of the columns line up with the hole in the bottom – and the brass won’t fall out prematurely.

.webp)