FAQ

- Support System

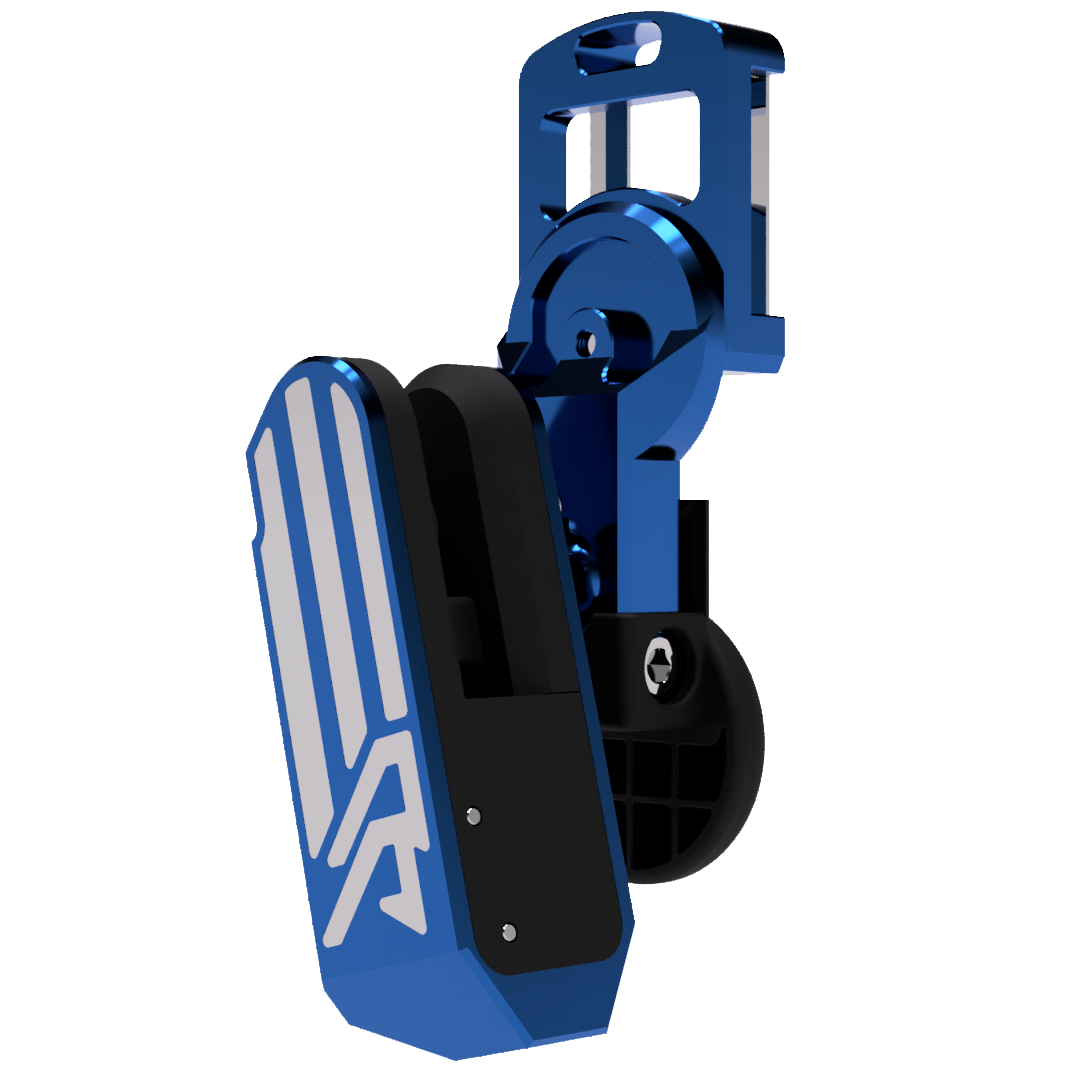

- DAA PRIMER-PRO Collator

- Primer Pro - Troubleshooting

Primers sliding too slow down the exit ramp on the Primer Pro

The cause: The cause is increased friction between the primer and the ramp due to some kind of oil or lube that remains on some types of primers after production. This seems to be more common with copper colored primers than silver ones, which are degreased before coating (we think). Since the primers are very lightweight indeed, it does not take much to make them slow down or even stick.

We did not encounter this much during our testing, partly because we ran the same primers through the machines again and again, and any lube on them got remove during repeat testing of the same primers.

The solution: Apply a little cockpit spray to the exit ramp using an ear-bud or similar applicator. Don’t spray it directly onto the ramp as that will be way too much. just spray some cockpit spray onto the tip of an earbud and run that up and down the ramp. Repeat as needed, depending on primers that should not be very often.

*Cockpit Spray is a type of cleaning solvent used to clear the inside cockpits of cars. It is cheap, available in any car/hardware store and is safe for all plastics. It cleans the plastic an leaves a little slick layer on it, which is great for reducing frictions and making the primers slide FAST.

If you have experienced this slow primer movement issue – give it a try. You will find it solves the problem effectively.

Font panel Activate Button appears stuck and does not click when pressed

The Activate Button is PCB-mounted and fitted into a plastic box on the inside of the side wall. Occasionally this box can be dislodged sideways in its rails. This can create contact and friction between the button’s body and the side wall pocket, making it stick. Wiggle the box a little to correct its position until the button is free. Pushing on the power-cord plug will likely move it in the correct direction.

Primers are getting stuck in the exit hole and stacking up on the ramp

- Ensure the exit hole is clear of any debris. Use a soft pipe-cleaner or a small brush to clean it periodically.

- Check your primer tube is well seated. Remember to spin it as you click it into place to ensure it is aligned.

- Make sure your primer tube has a small chamber on the entry hole. Not all primer tubes are equally good.

- Confirm the Primer Output Hammer is working correctly. It should momentarily be holding the primer against the side wall above the hole before it retracts, allowing the primer to drop. This can clearly be seen on slow motion video available on most smartphones.

- Make sure the Ramp Cover is in place and screwed tightly closed.

The Primer Disk seems to be rocking, not rotating smoothly

Possibly a primer has found its way under the Primer Disk and is interfering with its rotation. Lift it up off the motor shaft, remove all primers or other obstacles, and re-seat it. Make sure the Timing Lever is not caught under the edge as you seat it back down.

Getting Incorrect Primer Count

The count should load 98-100 primers in the tube. If any primers are left on the ramp, these are remembered and taken into account for the next tube. If the count is off:

- Clean the Exit Ramp

- Reset the counter by holding down the button until the LED flashes rapidly.

- Check that the small hole in the Output Ramp Slot, under the LED light is clean and clear of Debris.

Primer tubes filing too slowly (more than 2 min)

- Use 200-400 primers in the funnel for optimal speed.

- Keep the device clean.

- Try to loosen slightly the 5 screws on the bottom of the Primer Disk. This allows a fraction more space between the Primer Disk and the Timing Disk which can increase output speeds.

- Avoid using dirty or heavily corroded primers.

- Check that there are no primers permanently stuck in some slots between the Primer and Timing Disks. If too many slots are blocked, output speed decreases. Use a toothpick or plastic rod/pin to push them back from the outside towards the inside (back into the funnel). Avoid using a metal tool which can damage the slots. Try not to put these primers back in use – most likely they are out-of-spec, with a deformed/damaged anvil which caused them to get stuck in the first place.

.png)

.webp)